Metamaterials have artificially created structures, to have properties that no conventional material has.

How do metamaterials work?

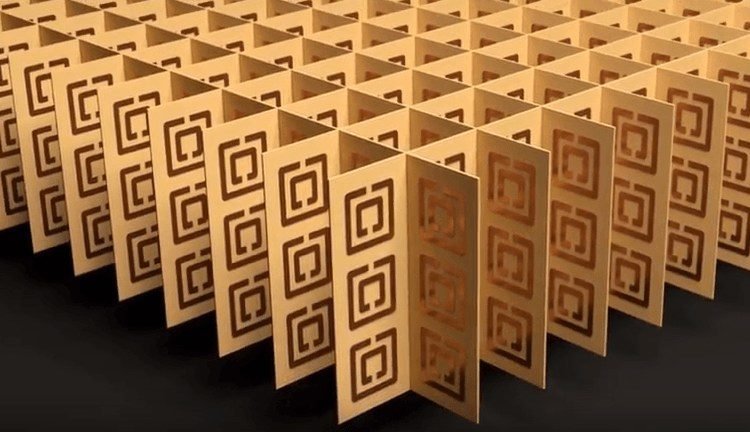

Metamaterials are made of nanostructures designed to obtain desired mechanical, thermal, optical, or electromagnetic properties. Nanostructures have dimensions on the nanometric scale, which can manipulate electromagnetic waves‘ properties. In conventional materials, chemical composition and covalent bonds determine properties. While on metamaterials, the nanometric structure determines properties.

The nanostructure is divided into cells, called meta-atoms, and each meta-atom has dimensions smaller than the wavelength of light, for which the metamaterial is designed. Nanometric scale allows the manipulation of waves on infrared and invisible light frequencies.

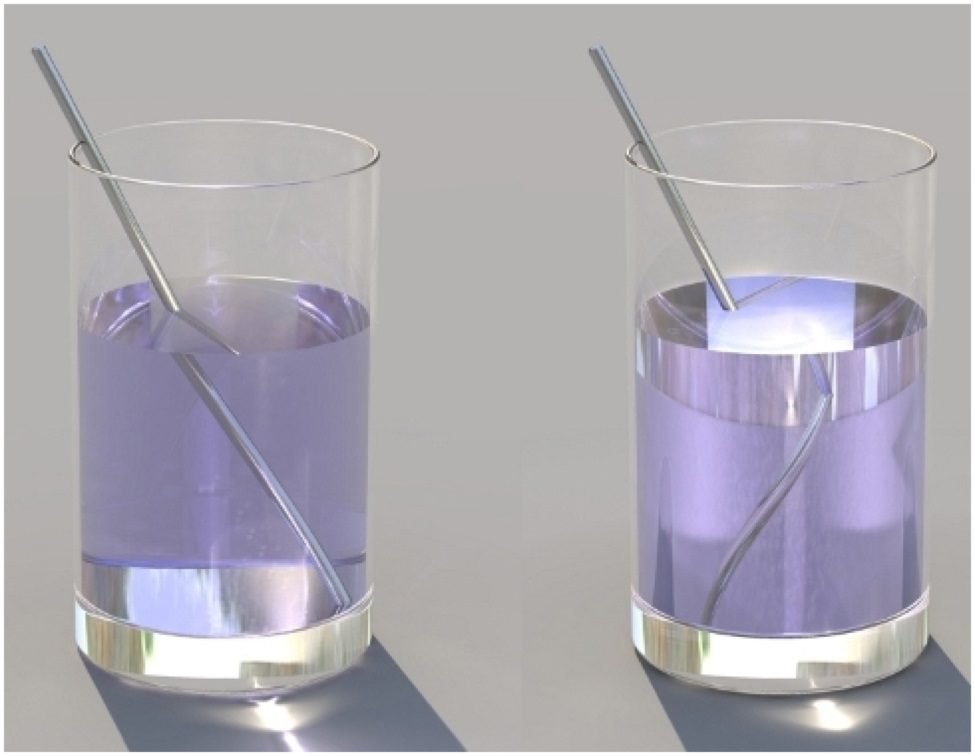

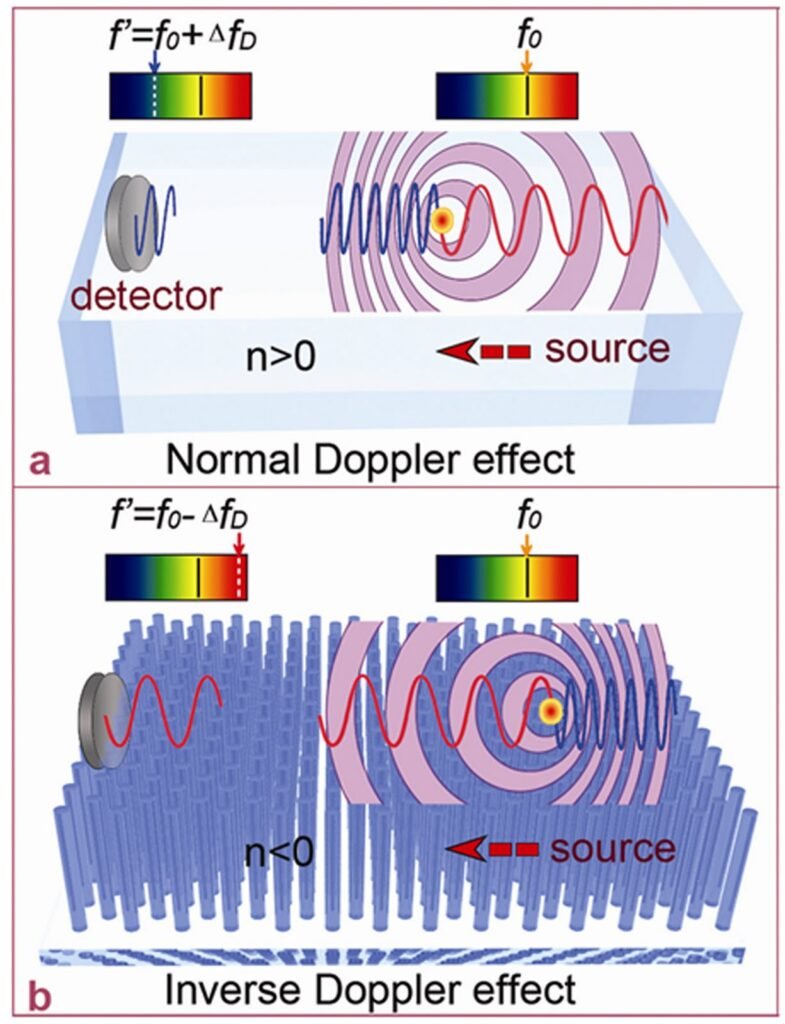

Negative refractive index

It’s possible to build metamaterials with a negative refractive index, which produces many eccentric optical phenomena. In 1969, the Russian physicist Victor Veselago was the first to suggest the existence of this type of material.

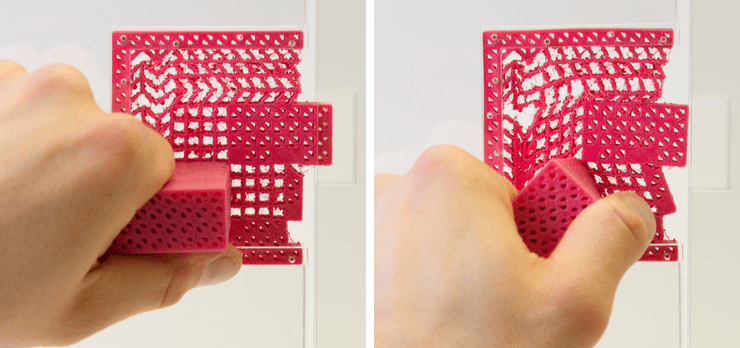

Mechanical metamaterials

They are 3D printed and have a combination of rigid and flexible cells for many applications. Researchers from Hasso Plattner Institut, in Potsdam, Germany, developed these materials.

In addition to this, exist acoustic metamaterials, whose nanostructures also can be printed in 3D. These materials can manipulate sound waves like electromagnetic waves, with many interesting applications.

Some applications

- Some researches use metamaterials to build antennas for 6G communication networks. I published news about the subject.

Antenna for 6G networksClick here

- There is the possibility to build lenses with different sizes, shapes, and materials, which works better than traditional lenses.

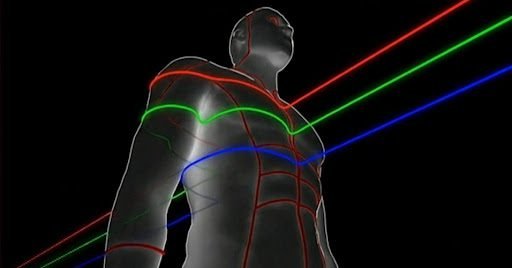

- The manufacturing of invisible cloaks, like in movies and video games, made of materials that bend the visible light.

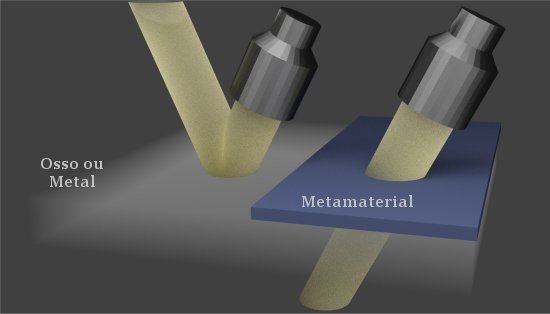

- Ultrasound exams can use metamaterials to observe inside the body with more details and precision.

It’s a promising technology and it’s not possible to post all applications. The biggest current challenge is to create a method to produce at a large scale.