In this post I will explain how the LCD are made. Click in the following button to see the post about the working of LCD.

LCDClick here

LCDClick here

Materials

Here are the materials that compose the LCD.

The liquid crystal stays between two polymer layers, the LCD’s glass is coated with silicon dioxide to polarize the light and it is made of borosilicate to avoid the ions to modify the electrical field and consequently the crystal’s alignment, the silicate dioxide is to stop the passage of ions. Transparent electrodes are made with a layer of indium tin oxide and lithography (I will create a post about this process with more details).

Manufacturing mode

To make a LCD, first you have to wash, polishing and cut in the right size. The polishing is made with this process.

The glass must be cut with a diamond saw.

The glass must be cut with a diamond saw.

After that the glass is coated with silicon dioxide. The next step is to put the transparent electrodes in the glass substrate and for that you must coat it with indium tin oxide, put a photoresistive layer above and use a mask to apply the photolithography process, similar to the process of manufacture chips.

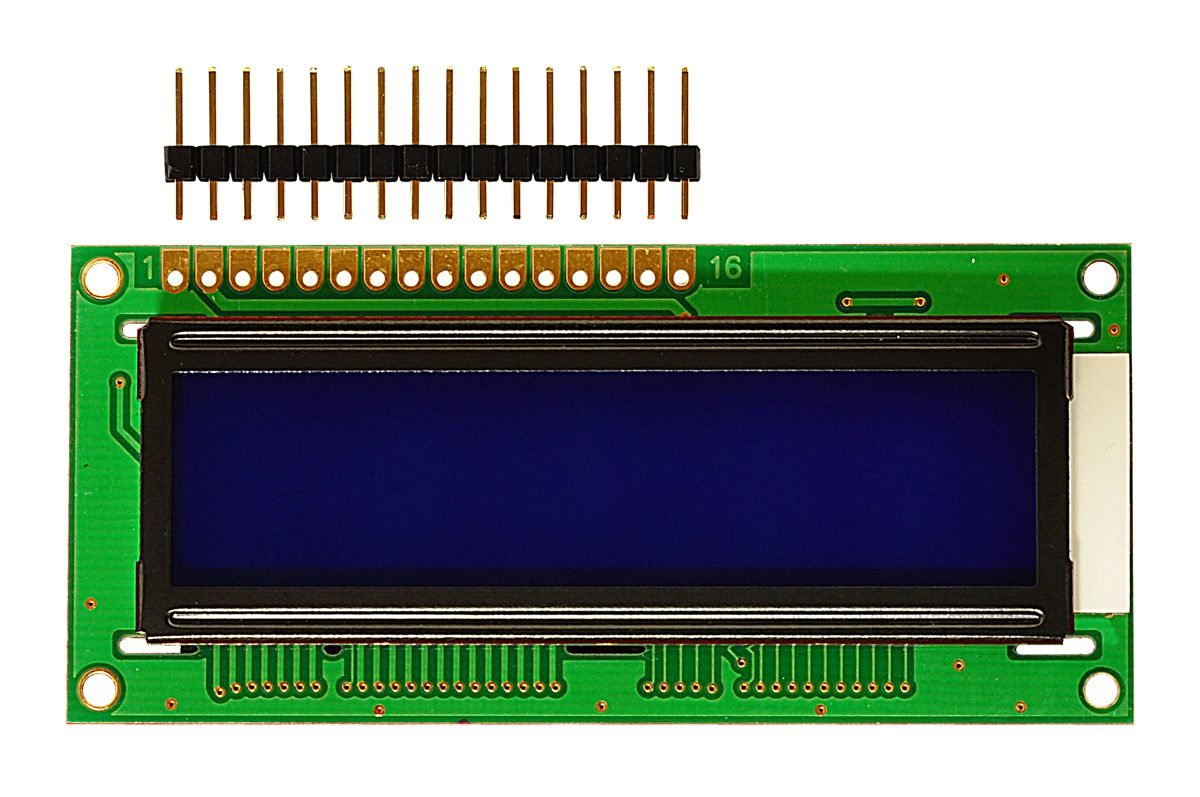

The next step is use a polymer film of polyamide to coat the substrate with electrode to align the liquid crystal with the substrate. Then the liquid crystal is finally injected between two substrates, the LCD cell should have between 5 to 25 micrometers. Finally build the electronic circuit to control the LCD.