I will give an introduction to how wind turbines work.

The blades

The blades of wind turbines have an aerodynamic form that can spin by the power of winds. It uses the same airfoil principle. This principle says that the pressure below the airfoil is greater than above because the air moves faster above the wing due to greater curvature.

The material to make the wind blade must be the lightest possible, wind turbines use many composite materials, the figure below shows the blade’s interior.

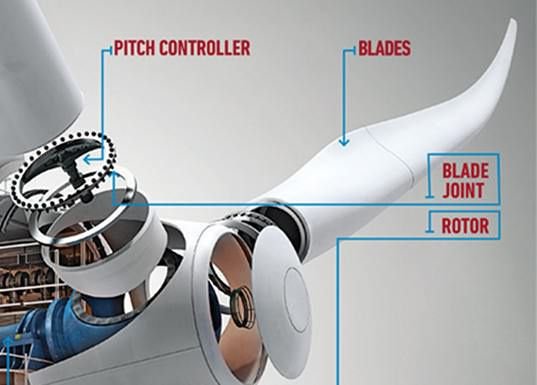

The blades have a pitch controller mechanism to make sure that the leading edge is always appointed to the direction of the wind.

Inside the nacelle

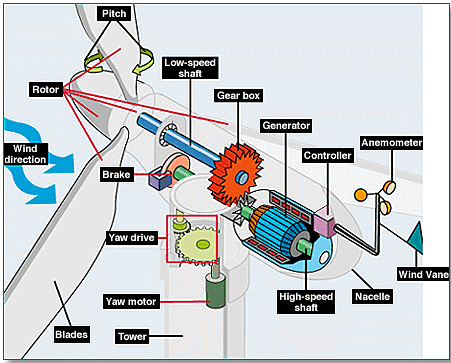

The propeller is coupled by a rotor with a gearbox with a planetary gear to achieve high speed, and the gearbox is coupled with a generator to produce electrical energy. Just as shown in the next figure.

This is the planetary gear.

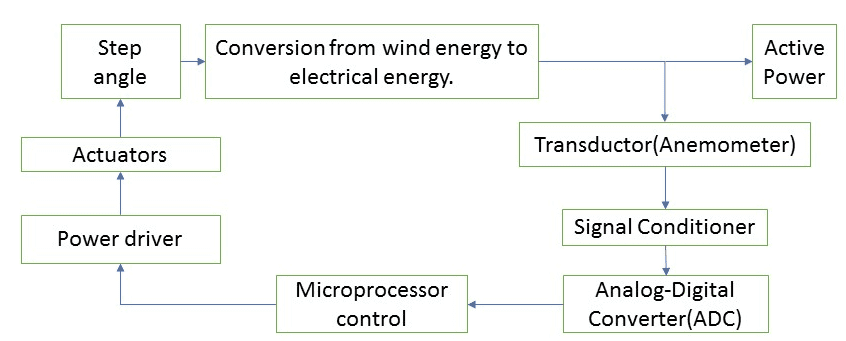

As the figure before shows, there is a break in the nacelle to protect the turbine from excessively windy conditions arresting the wind blade rotation, the anemometer measures the wind speed and direction, passing the signal to the controller to control the yaw motor to put the fan always in the wind’s frontal direction, it is necessary because the wind can change direction anytime. Here is a controller’s flowchart.

The electricity produced by the generator goes to a step-up transformer in the base of the wind turbine.

Efficiency

According to Betz’s limit, the maximum efficiency a wind turbine can achieve is 59,3%, because part of energy’s wind is converted into kinetic energy to spin the turbine, to have 100% efficiency you must take 100% from the wind, this would stop to flow and the turbine will cease to move. Here is the equation to calculate the efficiency of a wind turbine.

Ud – downstream velocity, wind speed after passing by the turbine.

Uu – upstream velocity, wind speed before passing by the turbine.

At – total area turbine.

ρ – air density (1.225 kg/at 15 ͦC and 1 atm).

This graphic shows that the best downstream/upstream ratio is 1/3, in other words, to have maximum efficiency the wind’s velocity passed through the turbine must be one-third of the initial wind’s velocity.

Why 3 blades?

Why do the turbines have 3 blades, instead of 4, 5, or 2? More blades mean more cost and more weight and you will have more torque and less speed and to produce electricity speed is more important than torque. The fewer blade will cause instability by spinning faster than necessary and the materials need to resist more stress, increasing costs. This video shows what happens when a turbine finds a violent wind.